self-braking motors

self-braking motors

Self-braking motors

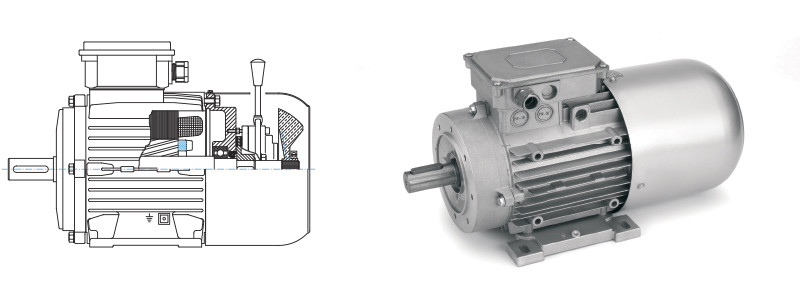

Self-braking motors are the asynchronous threephase and single-phase squirrel cage type. They have standard power ratings with electromagnetic disk brakes activated in direct current. Breaks activated in alternating current are also available on request; if necessary, motors can be customized by assembling the brakes expressly required by the customer. The motors are complete with power supplier housed in the terminal box. When the electromagnet of the brake is disactivated, the brake will operate owing to the action of a spring. Axial movement of the brake disk creates a braking action without transmitting pressure or impact to the bearings. The friction material is able to withstand high braking frequency. A manual disengaging lever is available on request.

Electromagnet

Activated in direct current, the electromagnet is very simple in construction and free from buzzing and vibration. The d.c. control keeps the drive current low and regulates the brake application time to a certain extent, i.e. the time that elapses from the moment in which the current supply is interrupted to the moment in which the braking effect begins.

Power supply

The power supplier is housed in the terminal cover of the motor and has been specifically designed to power the electromagnetic brakes with direct current. It is small in size, able to withstand high temperatures and is insensitive to voltage irregularities. Various types of power supplier are able to achieve activation times and braking torques differing from the rated ones.

Friction material

The friction material is free from asbestos and is notably wear-resistant. It possesses good thermal conductivity and a uniform friction coefficient even at high temperatures. The brakes are therefore able to bear high braking frequencies without being subject to fatigue. They are also insensitive to both dust and damp.

Gap adjustment

The gap (the value of the which can range from 0.2 to 0.8mm) is regulated by removing the fan cover and working on adjuster nut at the end of the shaft firmly in place by inserting a setscrew wrench in the fixing screw. The permissible number of hourly manoeuvres depends on the speed of the motor, the moment of inertia of the machine and on the braking torque.

Please consult our technical department for more details.

Self-braking motors are the asynchronous threephase and single-phase squirrel cage type. They have standard power ratings with electromagnetic disk brakes activated in direct current. Breaks activated in alternating current are also available on request; if necessary, motors can be customized by assembling the brakes expressly required by the customer. The motors are complete with power supplier housed in the terminal box. When the electromagnet of the brake is disactivated, the brake will operate owing to the action of a spring. Axial movement of the brake disk creates a braking action without transmitting pressure or impact to the bearings. The friction material is able to withstand high braking frequency. A manual disengaging lever is available on request.

Electromagnet

Activated in direct current, the electromagnet is very simple in construction and free from buzzing and vibration. The d.c. control keeps the drive current low and regulates the brake application time to a certain extent, i.e. the time that elapses from the moment in which the current supply is interrupted to the moment in which the braking effect begins.

Power supply

The power supplier is housed in the terminal cover of the motor and has been specifically designed to power the electromagnetic brakes with direct current. It is small in size, able to withstand high temperatures and is insensitive to voltage irregularities. Various types of power supplier are able to achieve activation times and braking torques differing from the rated ones.

Friction material

The friction material is free from asbestos and is notably wear-resistant. It possesses good thermal conductivity and a uniform friction coefficient even at high temperatures. The brakes are therefore able to bear high braking frequencies without being subject to fatigue. They are also insensitive to both dust and damp.

Gap adjustment

The gap (the value of the which can range from 0.2 to 0.8mm) is regulated by removing the fan cover and working on adjuster nut at the end of the shaft firmly in place by inserting a setscrew wrench in the fixing screw. The permissible number of hourly manoeuvres depends on the speed of the motor, the moment of inertia of the machine and on the braking torque.

Please consult our technical department for more details.